CDS Analytical is an ISO 9001 certified global provider of innovative thermal sample preparation instrumentation for the analytical laboratory. For over 50 years, CDS’s exclusive focus has been on conceiving, designing, manufacturing, and supporting leading edge instruments. CDS offers a complete suite of diverse front-end GC equipment including pyrolyzers, purge and trap, headspace, and thermal desorption systems.

ANALYTICAL PYROLYZERS

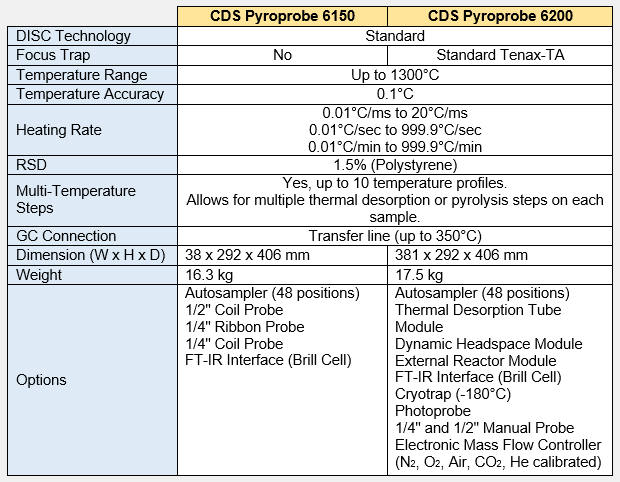

CDS Pyroprobe 6000 series are CDS’s 6th generation Pyroprobe for Pyrolysis – Gas Chromatography – Mass Spectrometry (Py-GC-MS). Both are equipped with Drop-In-Sample-Chamber (DISC) technology with easy sample loading. The system connects to any model GC with a heated sample line for easy on/off installation.

CDS Pyroprobe 6150 is the basic model while CDS Pyroprobe 6200 adds in an analytical trap to enable collecting analytes using slow rate pyrolysis for Py-GC-MS. The built-in trap expands the capability to use a reactant gas and perform thermal desorption on sorbent tubes.

PURGE & TRAP

The CDS 7000C Purge and Trap system features industry standard foam sensor, a newly designed wet trap and distinguished exchangeable sample pneumatics systems, all providing the highest available performance and unrivaled chromatographic resolution. The 7000C ensures plug and play connectivity to the world’s leading auto-sampler platform – the CTC PAL Robotic systems.

The CDS 8500C Purge and Trap system delivers the same combination as the 7000 series, but with plug and play connectivity to the CDS 8500A auto-sampler. The 8500C features a foam sensor, an inert coated wet trap and an 8 port pneumatics systems.

The CDS 8500A Auto-sampler is a 110 position auto-sampler with dynamic headspace sampling function for EPA methods 524, 624, and 8260 (both water and soil). A perfect match for the 8500C Purge & Trap concentrator with integrated software control.

THERMAL DESORPTION

The CDS 7550S is a stand-alone 72 position Thermal Desorption Auto-sampler for Thermal Desorption – Gas Chromatography – Mass Spectrometry (TD-GC-MS). Built on the 2nd generation auto-sampler platform, the CDS 7550S is capable of 3D positioning within 1 mm and could handle 3.5″ standard Thermal Desorption tube from any manufacturer. These features make CDS 7550 the most reliable Thermal Desorption auto-sampler available to the market. The 7550S adopts two focus modes as Pre-desorb/Pre-heat function for high humidity sample, and optional Peltier module for lighter compounds, to improve the resolution of early eluting peaks.

CDS EMPORE™

CDS Empore™, formerly 3M™ Empore™, Solid-Phase Extraction (SPE) products utilize the patented high density membrane technology to maximize extraction efficiency with minimal elution volumes and less matrix interferences. Offered in disk, cartridge, 96-well plate formats, and StageTips, CDS Empore™ SPE products are perfect for environmental, food and agricultural, biopharmaceutical, clinical diagnostic, and proteomics applications. CDS Empore™ is committed to maintain the same formula and manufacturing process to continue to deliver high quality and cost-effective Empore™ products that have been delivered to customers for more than 30 years.

PURGE AND TRAP

Purge and Trap, invented in the 60s in response to the Clean Water Act, is the most effective method to answer these challenges for extracting and concentrating volatile organic compounds (VOC) from liquids and solids. The Purge and Trap process involves purging the sample with an inert gas in a sealed environment (sparge vessle) at the appropriate temperature. The gas going through the sample will establish thermal equilibrium with VOCs in the sample, therefore transferring the VOCs from an aqueous state to a vapor. After eliminating the moisture through the wet trap, the gas is then swept to an analytical trap that absorbs and retains the VOCs , where they are transferred to the Gas Chromatograph for further analysis.

PYROLYSIS

Pyrolysis is a thermal decomposition process of organic material at elevated temperatures in an anaerobic environment. It involves the cleavage of large complex molecules into smaller, more analytically useful fragments by the thermal energy.

As an analogy, a Mass Spectrometer shatters compounds using electron impact, the compound is fragmented in a reproducible way, the ions are separated by the MS and the result is a spectrum which is both qualitative and quantitative. Pyrolysis works in much the same way. By applying heat to a sample that is comparable to the energy of specific bonds, the molecule will fragment in a reproducible way. The fragments are then separated by the analytical column to produce the chromatogram (pyrogram) which contains both qualitative and quantitative information. The number of peaks, the resolution by capillary GC, and the relative intensities of the peaks permit discrimination among many similar formulations, making pyrolysis a powerful tool in the identification of unknown samples.

THERMAL DESORPTION

Thermal desorption encompasses two primary functions: sample collection/concentration and transfer to a detector.

The use of adsorbents and large sample volumes to collect vapor phase compounds, (such as VOC’s in air or residual components from solids), facilitates accurate analysis even when sample levels are very low.

Organics are concentrated on sorbent media while the sample matrix, air or water, is discarded. In much the same way as a vacuum cleaner filters dust from air as it sweeps over a surface, Dynatherm instruments capture compounds of interest on adsorbent material packed in glass cartridges. Collected compounds are then introduced into another analytical instrument, typically a gas chromatograph, where they are separated, measured, and identified.

Thermal desorption uses heat, (instead of solvent extraction), to release organic compounds from the adsorbent and transfer the entire collected sample to a gas chromatograph for analysis. This eliminates extraction time, (typically 12-24 hours), a solvent peak in the chromatogram (which can mask compounds of interest), and waste solvent disposal, an increasing expense in many labs.

SOLID PHASE EXTRACTION (SPE) EMPORE

CDS Analytical LLC, the global leader of gas chromatography (GC) sample introduction instrument for the analytical laboratory, has signed a definitive agreement with 3M Purification Inc to acquire the rights to Empore™ products, including production equipment related to manufacturing 3M™ Empore™ products, know-how in product formula, process standards, quality control, specification, and the Empore™ trademark. 3M will also license certain patents to CDS Analytical related to the Empore™ products. The transaction is expected to be completed in the first quarter of 2019.

With this acquisition, CDS Analytical extends its reach into lab consumables and lays the foundation to expand its offerings to Environmental, Food Science and Biopharma customers, while creating opportunities to establish one-stop shop by covering both SPE instruments and consumables. The acquisition will combine the power of the CDS Analytical’s cutting-edge technology in analytical instrument with Empore™ brand’s legendary membrane formula in separation science to drive behavior change with CDS Analytical’s expertise in analytical chemistry and proven ability in manufacturing high quality products over the past 50 years.

TUBE CONDITIONER

CDS offers two conditioners to restore tubes to their original purity, which are single tube model and sixe tube model. The six tube model has independent flow control for each tube, and is supplied with a handheld controller for easy control. The six tube conditioner could also be connected to a PC for programming. The injection port option is available to allow users to spike the tube with an internal standard.